This is a spectacular N scale model built with a choice of open or closed hatches, or none at all. It is from an actual Danish design, with some modifications to make it feasible for N scale. This class of feeder ship debuted in the early 1990s, and new ones are still being built. This ship has a capacity of about 650 TEUs, or 325 40′ containers.

At just over 28″ long, it will fit in small harbors or on N Trak modules. I’ve painted this one in Maersk colors, bit I’ve seen this class of ships all over the world, either in person or through Google Earth, from both large and small shipping companies. I’ll be developing some options, such as different rescue boats and crew amenities.

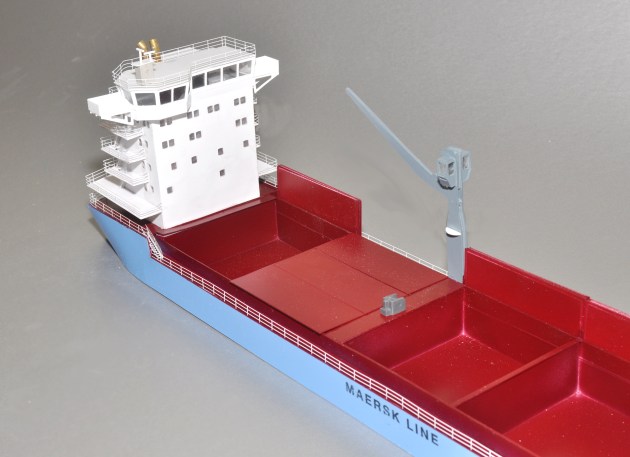

All six holds can be modeled open or closed; but the forward hold has a center keel to stabilize the bow. It has custom photo-etched railings and stairways, and many custom details such as winches, masts, ventilators, davits and lifeboat.

This shows the open holds, the self-unloading crane, and the modern superstructure:

The ship has very clean lines:

Because it is an “empty” hull, the model is built up from styrene, but the hull goes together as easily as a hull can, and requires minimal fitting and trimming.

A built-up model, custom painted and decaled is $950.00 US, plus shipping and insurance.

A complete kit containing all details (but not commodities like paint and glue) is $375 US, plus shipping.

Here’s a version I recently built for a customer in France. It shows some of the possibilities that this model has, and some of the developments I’ve incorporated.

Above is the ship being unloaded. I incorporated different, center-mounted hydraulic cranes. You can see the second and sixth hatches are open, showing the top level of the below-decks storage. Also shown are 45 containers that I cast, painted and decaled for “CGN,” a fictional company.

The ship now includes a modern free-fall rescue boat and rack, and full-width hatches supported by buttresses at the hull edge. The hatches are in eleven segments, and show where many of the attachment points are.

The above shows the bow detail and the empty second hold, which has a dummy platform that raises a row of containers to the correct height just below the deck. A new bow configuration goes on smoothly, with no buckling tendencies, and looks great to boot! This ship will be a proud addition to his layout.

May 13, 2017: More Versions in Z Scale

Here is a slightly earlier, less expensive (in real life) version that perhaps a charitable foundation would buy rather than the latest, most expensive versions. The bridge is much simpler; the cranes just a bit less capable, and the rescue boat has a side “free” release. Brely noticeable are the platforms included for the open holds. These position a row of containers at the correct height.

While the spotlight is often on the now 20,000 TEU ships that ply transoceanic routes, these smaller feeder ships far outnumber them. Here is another Maersk version, with a note that Maersk and many of the transoceanic lines are abandoning this class, leaving the traffic to smaller operators. All the hatches are closed on this version. Only the No. 1 hold can’t be portrayed open–No 1 can be open, but requires some extensive surgery on the bow interior structure.

1.1K Modern Container Ship Kit

The kit for the modern feeder container ship contains 3D printed parts such as the superstructure, bridge, hatches and hatch coaming, side hatch supports, and other deck accessories, leading to a quick build. US shipping ($20) is included; international shipping please contact peterknolan@gmail.com

$370.00

1.1C 375′ Modern Container Ship (N and Z)

The 375′ Modern Container ship represents the large portion of ships not in scheduled international travel. Includes your choice of colors, name, homeport and post and boom assemblies. Price includes $30 for US shipping. For international, please contact peterknolan@gmail.com.

$980.00

I am very interested in purchasing the 375 Modern Feeder container ship kit for my scale set-up under construction. How many hours would you estimate for an intermediate to advanced modeler to build excluding painting? How do I purchase it from you.

It is hard for me to estimate how many hours this would take, so the following is given with the proverbial grain of salt. It probably takes more time to figure out where everything goes than it does to assemble the parts. The hull consists of two inner keels, a laminated bottom, strips for the main deck, laminated hull sides (applied one at a time), and the sections. I would estimate 4-8 hours, using lots of masking tape. The house is actually fairly simple and square, so 4 hours for a basic build, plus a few hours for the bridge. Applying railings and stairways is probably another 4 hours. Applying details takes perhaps two hours. The rescue boat structure may take a few hours. These are my best estimates from people who have reported their progress to me. I can, of course, build them much more quickly, and so can you, when you are building your second one 🙂 There may be some filling and sanding of the hull required–if you are precise and take care with alignments, this can be eliminated or greatly reduced. Once you start further detailing, then it’s a matter of how long you want to work on it–some ships, like model railroad layouts, are never finished! I would guess that it would take you less than the estimates given above.

The preferred ordering mechanism is through Paypal to peterknolan@gmail.com. Or drop me an email to the same address if you would like to pay by credit card or check. –Peter

Intially contacted you before you left on your vacation in April. Just have a couple questions: What is the width of this model? Are separate plans included in addition to those provided on your website? Your plans, in some cases, laminating two pieces together. Do you recommend a special way of doing this or is it a simple gluing of the two pieces together sufficient? Is their a particular glue, bonding agent you personally use and recommend? Last, what would the shipping costs be if sending to Belton, Texas 76513?

I am still on a vacation of sorts, as the entire business is boxed up and ready to move to Alabama. Due to my travels, I couldn’t schedule a move before June 29. Drat–but that’s the way things worked out. To answer questions in order: this model is 115mm or 4.53″ wide. That is a prototypical 60.3 feet. Separate printed plans are not usually included, but rudimentary plans can be upon request. The reason is that many “plans” or more accurately cutting paths are developed mathematically and don’t relate readily to the customary orthogonal views. A plan or profile view may be first modified for camber, then for sweep, then for curvature, and then “faired” against known dimensions, resulting in further modifications and often a next iteration. Yes, I do recommend laminating many parts together for two reasons. My cutters don’t do well with thicknesses above .020″ styrene, and often 0.40″ styrene or more is required for stiffness. Secondly, the laminated pieces seem stiffer than a single piece cut from thicker stock. I glue about a three-inch section at a time, being careful to maintain alignment–I’ve done 12-inch sections without a problem, but I am experienced! I used Testors liquid cement without a problem, but that gets expensive for larger projects. So I now use a formulation of about 75% MEK (methyl ethyl ketone) and 25% toluene. The percentages are not critical as I’ve used 70/30 and 80/20 with success. The toluene acts to slow things down. Shipping costs for a kit to Texas will be about $12-14. Peter Nolan

If you are in the midst of a move, when do you think that you would be able to fulfill a kit order for this ship? Thanks. Ken

Early to mid-July. I just have to set up the cutters.

OK, I’m interested in buying this kit. Guess I’ll check back in with you mid July so see if you have one to sell.

Ken

Is the hull on this model watertight (if assembled correctly) such that this model can float in a small water model?

The fit is certainly precise enough for watertight construction although special attention would be needed at the bow and stern. I think you would want a full hull model (or approximation) in order to get the weight well below the waterline. As constructed this ship will float, but upside down! The waterline model would require a lot of weight below the hull, which would reduce the freeboard (the height of the main deck above the water) very low–perhaps too low. I can build a full-hull model, but this model is on the small end for R/C on anything but swimming pool calm waters. Yes, I have seen Z scale self-powered ships probably less than 8 inches in length, but they are special cases in very smooth waters. Keeping this ship in this scale from rolling uncontrollably while underway would be a challenge.

Thanks for your response Peter. It would seem that my plan to make an operational N scale rail model of a Panama Canal lock – where railway “mules” can pull a ship through a (shortened) lock with appropriate equalising of water levels – might have even more challenges than what I expected.

Making the hull stable through the canal, I think, is the problem. Lowering the center of gravity below the center of bouyancy is the problem. All the superstructure serves as a lever to pull the ship upside down. It would take quite a bit of lead weight–probably ZAMAC weight these days, or tungsten if you can find and afford it–to keep the container ship from capsizing. If money were no object, a hull of cast resin would be a good starting point. I just don’t make a hull of cast resin that big. I think I’ve got a ruined blank of a fair-sized hull that I’ll lend you for experiments. It’s perhaps one-eighth the mass, but large enough to making scaling quite accurate. It’s solid resin, so it may sink right away, but then removing material would give you a good starting point.

Peter

Would like to purchase this model if you are still making them?

Yes, they are still available, now in sizes 266 feet to 415 feet in length. Prices are on the site at https://nscaleships.com/n-z-scale-ship-index/new-266-and-335-modern-container-ships-also-415/ and https://nscaleships.com/n-z-scale-ship-index/375-modern-feeder-container-ship/. Payment is preferred via PayPal to peterknolan@ gmaill.com.

Pricing

“A built-up model, custom painted and decaled is $950.00 US, plus shipping and insurance.

A complete kit containing all details (but not commodities like paint and glue) is $375 US, plus shipping.”